Talk to us,Get a Solution in 20 minutes

Please let us know any requirements and specific demands,then we work out the solution soonest and send back it for free.

Please let us know any requirements and specific demands,then we work out the solution soonest and send back it for free.

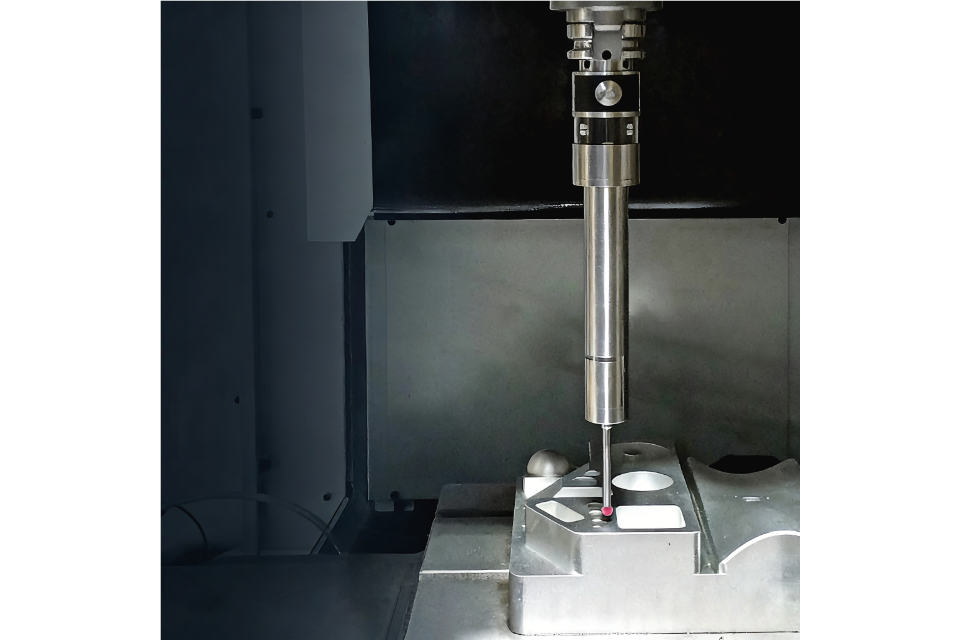

If you’ve ever set up a part, hit “run,” and crossed your fingers hoping the finished part falls within tolerance, you know the hesitation that comes without real data. On-machine probing flips that script. Instead of relying only on fixed fixtures, manual measuring, or separate CMM machines, probing lets your CNC actively inspect and verify parts during setup and production — and Siemens makes this workflow both capable and practical.

On the shop floor, inspection isn’t just a quality department task — it’s part of the machining process. Siemens’ probing workflows allow you to:

The idea is simple: use your machine as both a cutter and a measuring device so that each part is verified in context, instead of being sent off to a separate metrology lab. That’s what “inspection on machine” means — and it’s a big productivity win.

Learn more about Siemens’ CNC probing solutions cnc-probe.

Instead of viewing a probe as just a fancy edge finder, Siemens integrates probing directly into the workflow:

Before any cutting happens, the probe can measure:

This pre-machining validation gives you confidence that the part is where the CNC program thinks it is — reducing scrap and rework.

Once the part has been machined, on-machine probing lets you:

Fresh off the toolpath, the machine can tell you in real time whether the part meets the spec. That saves time and avoids surprises later in the process.

Discover more about the CNC modular touch probe cnc-probe.

One of the most powerful aspects of Siemens probing workflows is that the workflow isn’t static. If a measurement reveals variation — in fixturing, stock size, or machine alignment — the workflow can:

This is where on-machine probing becomes intelligent inspection rather than just a simple stop trigger.

Imagine a batch of parts where the raw stock size varies slightly from piece to piece — something common with castings or irregular blanks. If you cut based on a fixed program without checking the actual stock:

With Siemens on-machine inspection, your workflow might look like this:

This gives you a measurement-driven machining process, not guesswork.

Explore the Z-axis wired tool setter cnc-probe.

Before any inspection cycle works well, the probe itself must be trusted. That starts with good calibration:

Siemens documentation on probing cycles (e.g., for their 840D sl / 828D controls) emphasizes probe calibration as a prerequisite for accurate measuring operations. This isn’t a one-off task — calibration ensures that the probe’s recorded contact points truly reflect the physical reality of the part being inspected.

Read more about high-precision measurement with CNC probes cnc-probe.

Here’s a distilled look at how a probing inspection workflow typically flows on Siemens-equipped systems:

This structured approach puts the probe at the center of both setup and quality validation — not just a one-time trigger tool.

Learn more about our CNC infrared touch probes cnc-probe.

Compared to generic “touch probe stop here” descriptions, Siemens probing workflows:

These aren’t just isolated probe stops — they’re data-driven decision points in your machining process.

Explore more about Siemens’ probing technology cnc-probe.

Shop-floor inspection is no longer about just checking a part after the fact. With Siemens probing workflows, inspection becomes a driving factor in your machining process:

Probing becomes part of the machining logic, not just an add-on.

If in the past you treated setup, machining, and inspection as separate stages, probing workflows on Siemens equipment blur those boundaries in a good way. Inspection becomes:

That’s the future of shop-floor machining — not just making parts, but making parts with confidence.