Talk to us,Get a Solution in 20 minutes

Please let us know any requirements and specific demands,then we work out the solution soonest and send back it for free.

Please let us know any requirements and specific demands,then we work out the solution soonest and send back it for free.

We often talk about probes and tool setters like they’re interchangeable, or think everyone inherently knows the difference. But on the shop floor, that assumption can lead to confusion — especially when you’re trying to automate setups, reduce scrap, or move toward lights-out machining.

This blog not only explains what each device does, but why they exist, when you use them, and how they complement one another in a real machining workflow.

At a glance, both tool setters and work probes involve contact between the machine and something being measured. But their focuses are fundamentally different:

Tool Setters are all about the tools themselves — measuring lengths, diameters, wear, and breakage. They help the controller understand what the cutting tool is before you ever make a cut.

Work Probes (part touch probes) are about the workpiece — finding the position, orientation, and key features on your stock so the machine knows where the part is in space.

One looks inward at the CNC’s own cutting tools. The other looks outward at the material you’re about to machine. They serve separate purposes, but both feed essential data into the control so your machining run behaves predictably.

Learn more about high-precision CNC laser tool setters cnc-probe.

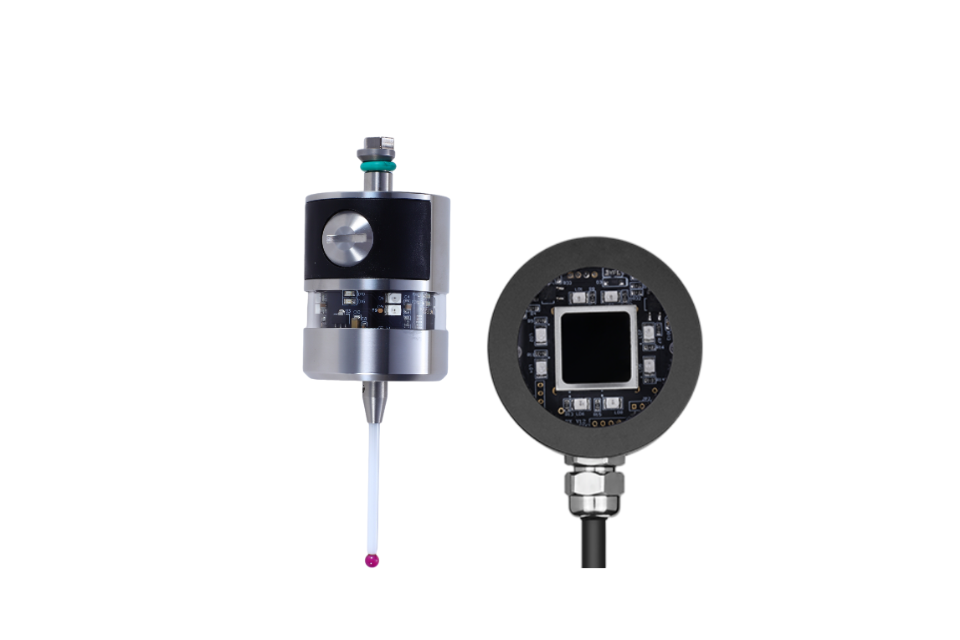

A tool setter (sometimes called a tool setting probe or automatic tool setter) is a device or sensor specifically designed to measure the cutting tool itself — including:

In some systems, even thermal growth compensation during machining.

Tool setters are usually mounted on the machine table or an accessory arm. The tool is brought into contact with the setter, the setter generates a signal, and the CNC control uses that signal to calculate and store the tool’s dimensions.

This data feeds directly into:

In short: tool setters make the tools trusted before cutting begins.

Check out CNC modular touch probes cnc-probe.

A touch probe is about understanding the workpiece’s position and geometry. When you mount a new part, especially if it’s:

You need to tell the machine where that part actually lives in XYZ space. That’s where a work probe shines.

A work probe does this by:

Instead of relying on assumptions or manual measurements, the machine itself learns the part’s orientation and adjusts its coordinates accordingly.

Explore CNC single-axis wired tool setters cnc-probe.

Think of it this way:

You could have a perfect pencil and still draw off the page if your starting point is wrong.

That’s exactly why combining both in a workflow matters. One alone isn’t enough for precision machining — tool setters make the tools precise, work probes locate the part precisely.

Check out CNC transmission wired touch probes cnc-probe.

Here’s a subtle but important point many vendors gloss over: not every shop needs both at the same time, but understanding the why behind each determines your investment and process.

Tool setters can automatically update the control and reduce manual data entry and errors.

Work probes streamline setups and ensure the machine knows what’s on the table.

Visit CNC Probe homepage cnc-probe.

Some probing systems can be versatile — meaning the same physical probe hardware might perform both tool setting and work probing. That’s especially common with spindle-mounted probes that can measure both tool and part features.

But even then, it’s helpful to think about the tasks separately:

Keeping that mental division clear helps you build workflows that are predictable and auditable — not guesswork.

Explore high-precision measurement CNC probes cnc-probe.

Learn about CNC optical wired five-axis CNC touch tool setters cnc-probe.

Here’s what happens when you:

You get:

This dual-data approach is what separates experienced CNC shops from ones that still rely on manual dial indicators and edge finders.

Tool setters and work probes both measure, but they measure different truths:

By thinking in these clear, distinct categories — instead of lumping them together — you can design machining workflows that are both efficient and reliable, not just “automated” in name but truly data-driven in practice.