Talk to us,Get a Solution in 20 minutes

Please let us know any requirements and specific demands,then we work out the solution soonest and send back it for free.

Please let us know any requirements and specific demands,then we work out the solution soonest and send back it for free.

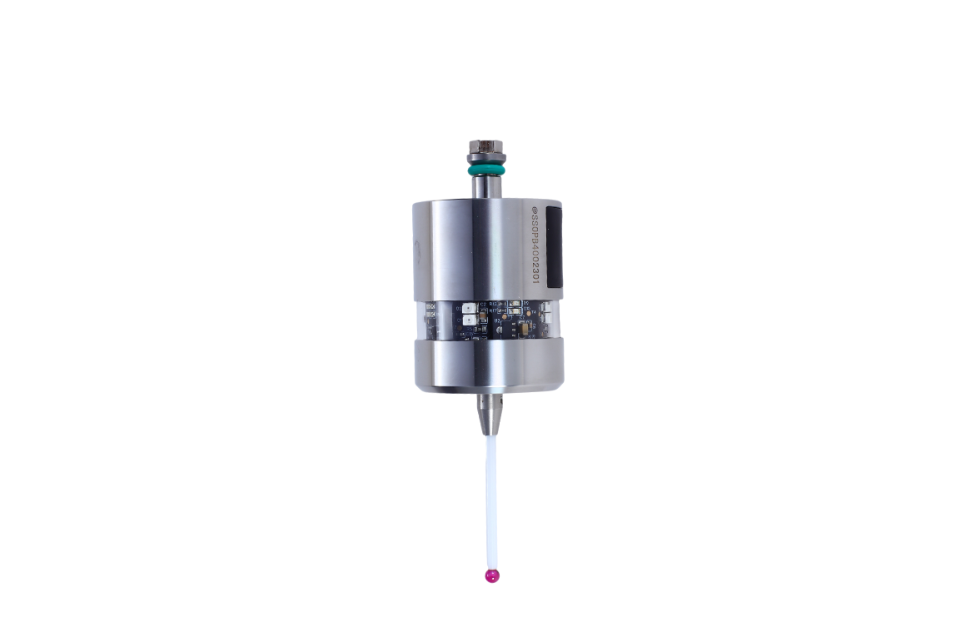

A CNC touch probe is a precision switch mounted in the spindle (or on the table) with a stylus. When the ball touches a surface, the probe sends a clean, repeatable trigger to the control. The control records machine position at that instant and runs a macro (probing cycle) to:

Think of a probe as the machine’s fingertips. The spindle doesn’t just cut—it feels.

Manual edge finding, dial tests, and shimming eat hours. A probe sets X/Y/Z zeros, squares stock, and finds centers in minutes, not half-shifts. On short-run and high-mix jobs, that’s pure gold—especially when paired with reliable CNC probing systems.

Probing verifies that the part is where you think it is. If a soft jaw shifts 0.12 mm, the macro knows—and compensates or stops. You get good parts faster, not just faster bad parts.

Mid-cycle checks (e.g., bore diameter or boss height) feed back to the control so you can auto-adjust tool wear. It’s SPC at the spindle: less drift, fewer surprises—one of the biggest advantages of modern CNC touch probes.

Whether it’s infrared (IR), radio, or wired, a probe lets the machine self-verify before moving on. That’s how unattended machining stops being a leap of faith, particularly in automated cells built around wireless CNC probes.

Well-built probes deliver ≤1 µm 2σ repeatability in ideal conditions. Real shops see a few microns—and that’s still game-changing.

| Method | Strengths | Watch-outs | Best for |

|---|---|---|---|

| Infrared (IR) | Fast, battery-friendly, no EMI issues | Requires line-of-sight; closed doors/chips can block | VMCs with clear receiver placement |

| Radio | Long range, penetrates doors/coolant, multi-machine | Slightly higher power draw; manage pairing | 5-axis, horizontals, larger enclosures |

| Wired | Zero pairing, immune to RF noise, lowest latency | Cable routing & strain relief; travel limits | EDMs, small VMCs, harsh EMI environments |

Pro tip: On horizontals and 5-axis, radio saves headaches. On compact VMCs with a clean window to the receiver, IR is simple and robust. On EDMs, wired wins.

Most modern controls (Fanuc, Siemens, Heidenhain, Haas, etc.) ship with canned probing cycles. If not, macros are short and portable. A good probe—like those featured on the Qidu CNC Probe homepage—usually pays for itself in weeks, not years.

3C & electronics, auto parts, aerospace, mold & die, and job shops all benefit from consistent probing routines supported by robust CNC probing hardware.

A touch probe turns your CNC into a measuring, learning machine. It shortens setup, raises first-part yield, keeps processes centered, and makes lights-out realistic. Whether you choose IR, radio, or wired, the payoff is the same: more good parts with less drama.