Hable con nosotros, obtenga una solución en 20 minutos

Por favor, háganos saber cualquier requisito y demandas específicas, a continuación, elaboramos la solución más pronto y enviarlo de vuelta de forma gratuita.

Por favor, háganos saber cualquier requisito y demandas específicas, a continuación, elaboramos la solución más pronto y enviarlo de vuelta de forma gratuita.

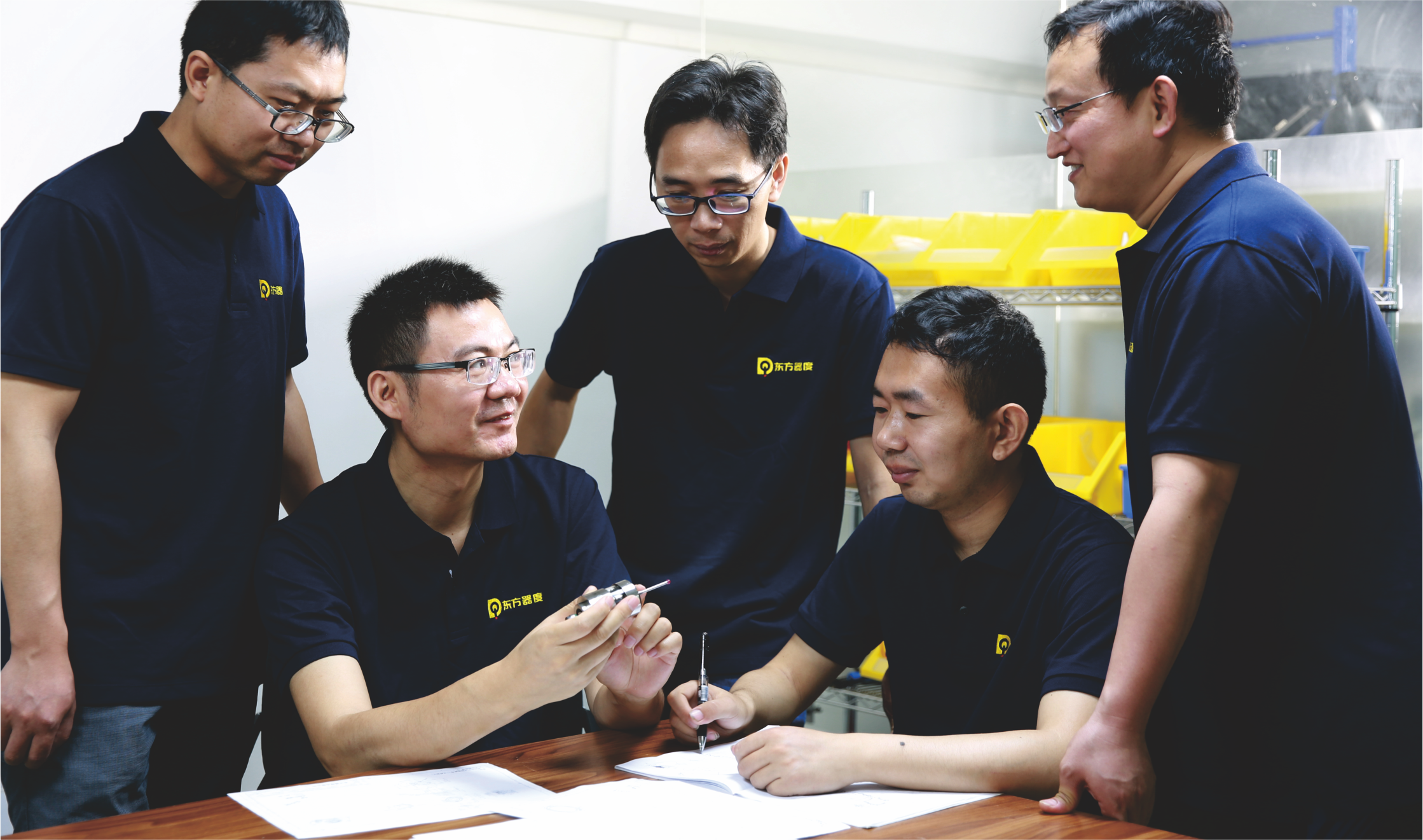

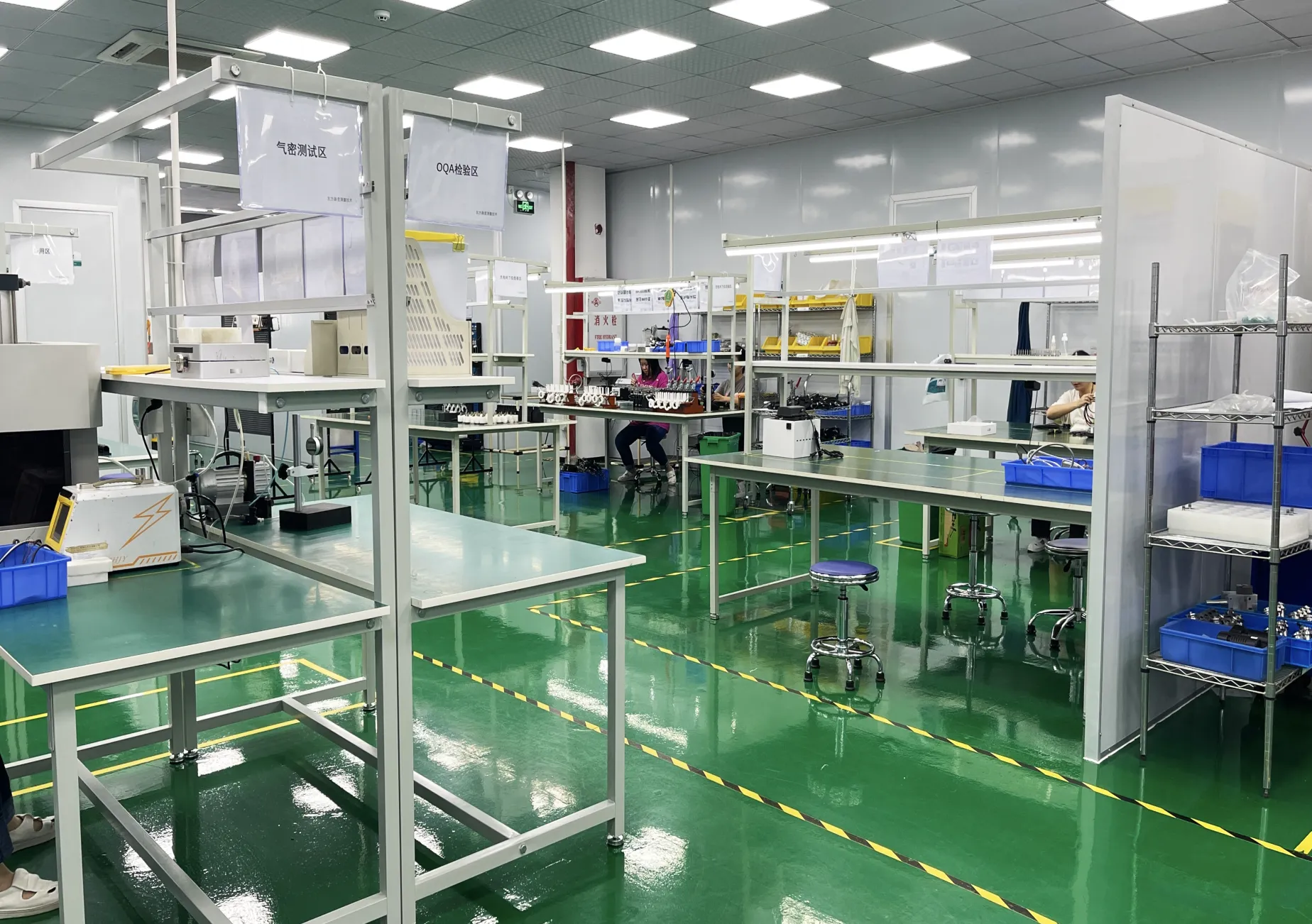

Nuestra empresa, Qidu Automation Technology Co., Ltd., está especializada en soluciones de medición de alta precisión en máquina, en concreto, sondas de contacto CNC y reglajes de herramientas CNC. Tenemos casi una década de experiencia en la investigación, desarrollo, producción y servicio de estos dispositivos de metrología avanzada.