ご相談ください、20分で解決します。

どのような要件や具体的な要求をお知らせください、私たちはすぐに解決策を解決し、無料でそれを返送します。.

どのような要件や具体的な要求をお知らせください、私たちはすぐに解決策を解決し、無料でそれを返送します。.

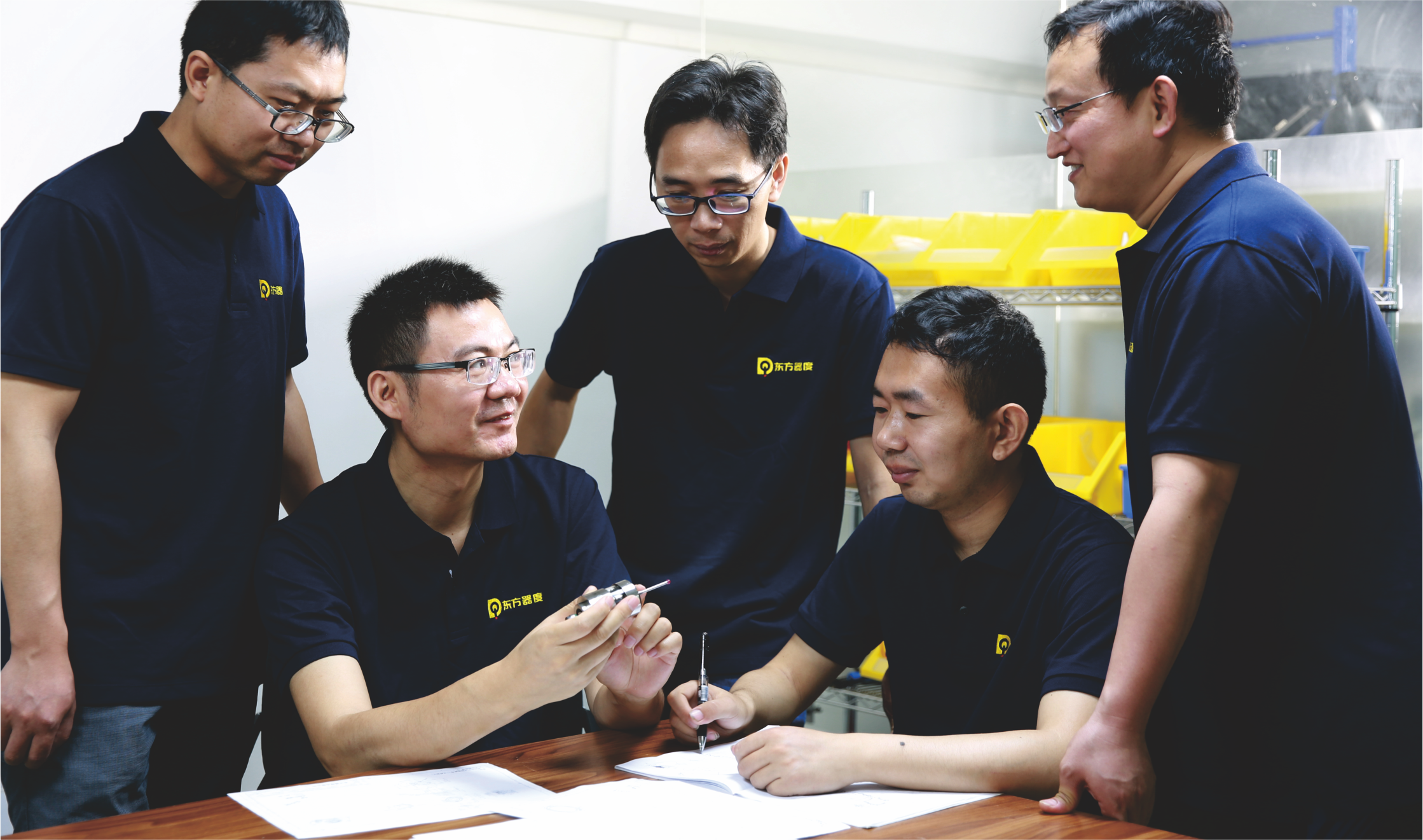

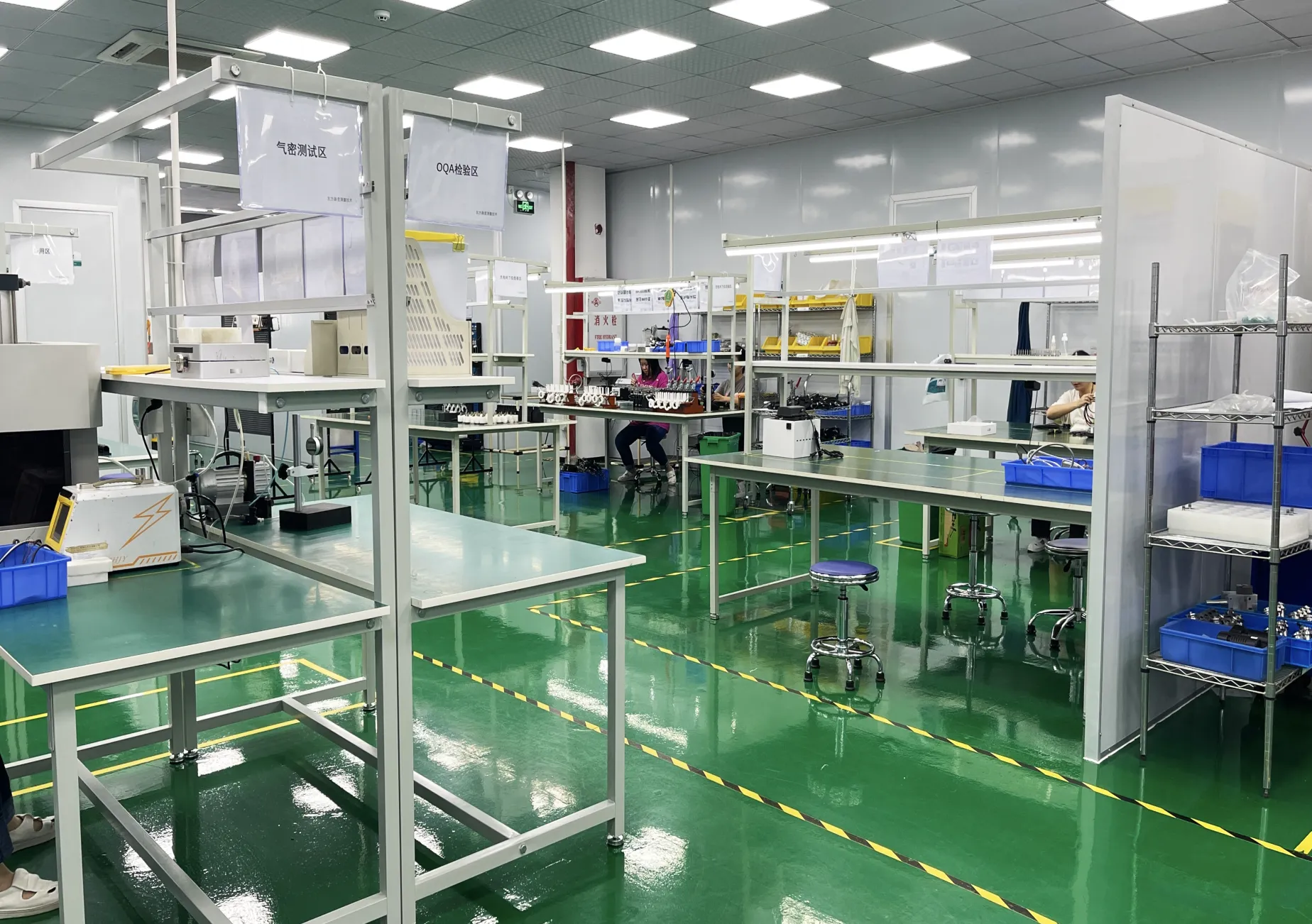

私たちの会社-奇度自動化技術有限公司は、高精度のオンマシン測定ソリューション、すなわちCNCタッチプローブとCNCツールセッターを専門としています。弊社は、これらの先進的な計測機器の研究、開発、生産、サービスにおいて、10年近くの経験を持っています。.