Talk to us,Get a Solution in 20 minutes

Please let us know any requirements and specific demands,then we work out the solution soonest and send back it for free.

Please let us know any requirements and specific demands,then we work out the solution soonest and send back it for free.

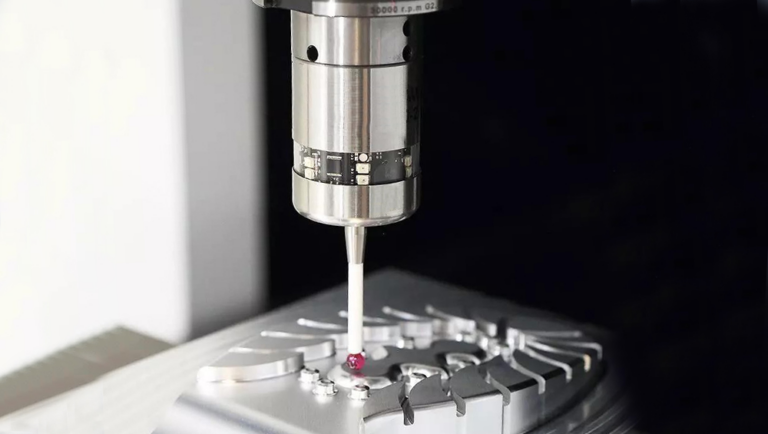

Finding a reliable 0,0,0 on your CNC — the point where X, Y, and Z all meet — is one of the first real steps to accurate machining. Whether you’re doing one-offs or production runs, nailing the zero means your program will hit features where it should. Traditionally, operators used edge finders, indicators, or simple visual alignment. But with a touch probe and the right approach — using plates, pucks, and probing routines — you get accuracy, repeatability, and confidence every time.