Talk to us,Get a Solution in 20 minutes

Please let us know any requirements and specific demands,then we work out the solution soonest and send back it for free.

Please let us know any requirements and specific demands,then we work out the solution soonest and send back it for free.

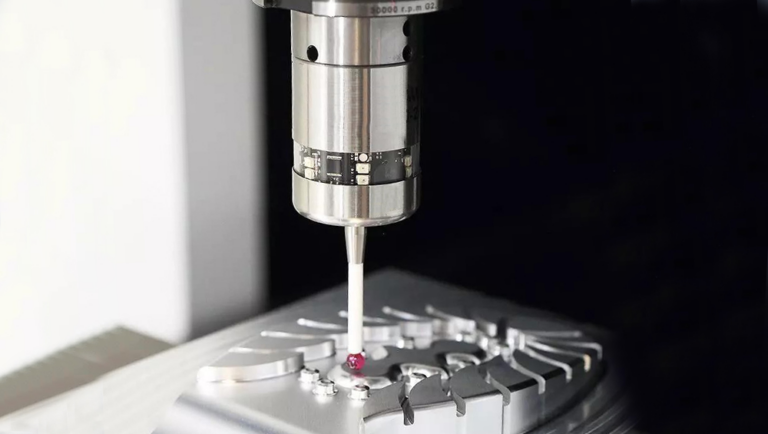

Finding the true center of round stock is one of those foundational setup tasks in CNC machining that can quietly wreck a part’s accuracy if done poorly. You might have used edge finders, manual indicators, or traditional center finders — and those tools still have their place. But a modern CNC probe can do this in a way that’s faster, more consistent, and dramatically less dependent on operator feel.

In this blog, we’ll break down why probing routines for center finding matter, how they’re better than old methods, and exactly what’s happening when you use them to find the center of round stock.

If you’ve ever stood in front of a mill with a vise full of parts and a clock that’s already running late, you know this feeling: you just want to find your zero quickly, accurately, and repeatably—without second-guessing yourself.

This blog breaks down what each tool is actually good at, where each one bites you, and how to decide—job by job—what to use and when.

Finding a reliable 0,0,0 on your CNC — the point where X, Y, and Z all meet — is one of the first real steps to accurate machining. Whether you’re doing one-offs or production runs, nailing the zero means your program will hit features where it should. Traditionally, operators used edge finders, indicators, or simple visual alignment. But with a touch probe and the right approach — using plates, pucks, and probing routines — you get accuracy, repeatability, and confidence every time.